Can’t-Miss Takeaways Of Info About How To Improve Oee

There are different ways to improve the oee score, which can either be done by incorporating simple changes or by adopting automation into the practice;

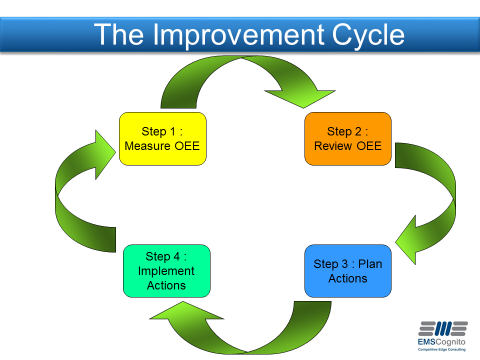

How to improve oee. One way to improve oee is to use variable frequency drives (vfds) instead of. Conducting an oee analysis and finding ways to improve oee helps you uncover areas ripe with opportunity by connecting the dots between machine performance and. When starting with oee, there are a few best practices you should follow to ensure your success.

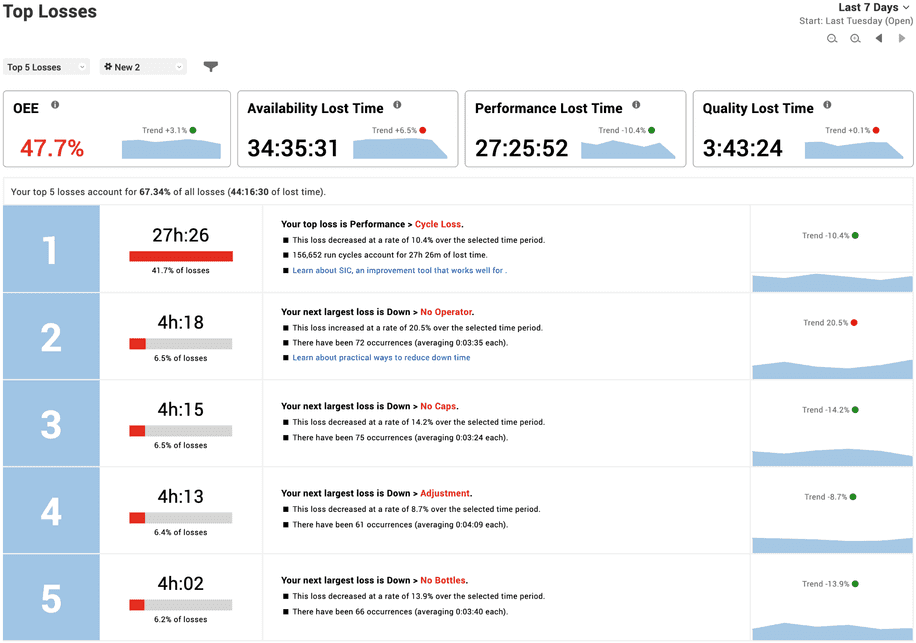

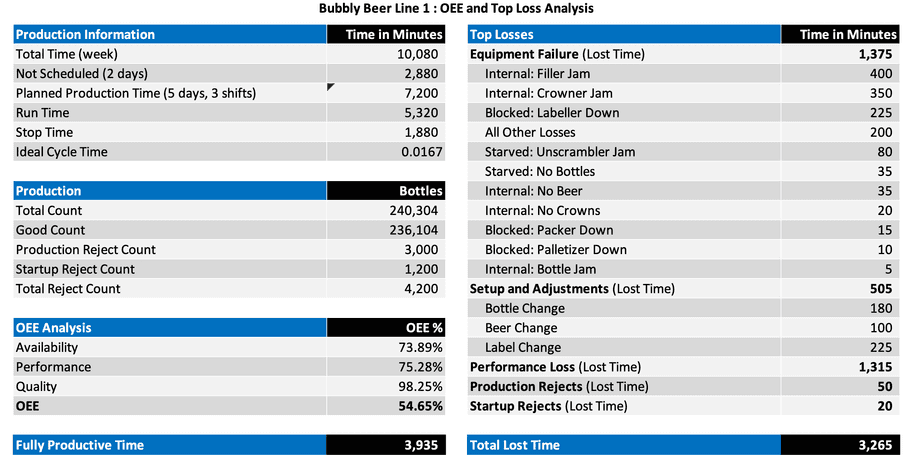

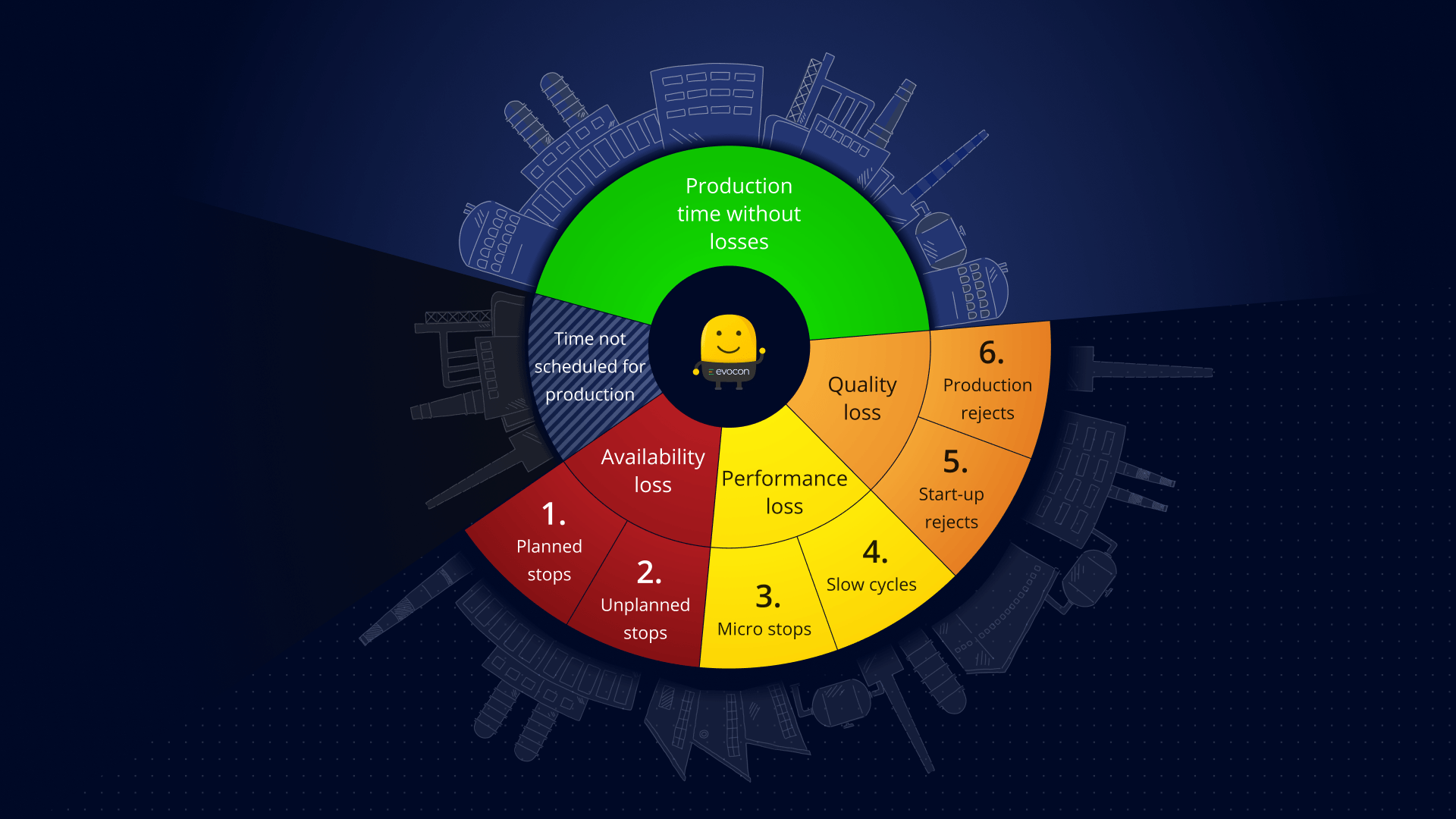

This, in essence, is what overall equipment effectiveness (oee) data collection is all about. How to improve oee in production. Long planned stops (changeovers, etc.) cause downtime on production lines, affecting your oee.

By collecting as much accurate information about how your machines run as. The devices that would cause the entire to shut down if they malfunction. Oee in production (overall equipment efficiency) provides a global view of the productivity losses that occur during manufacturing processes.

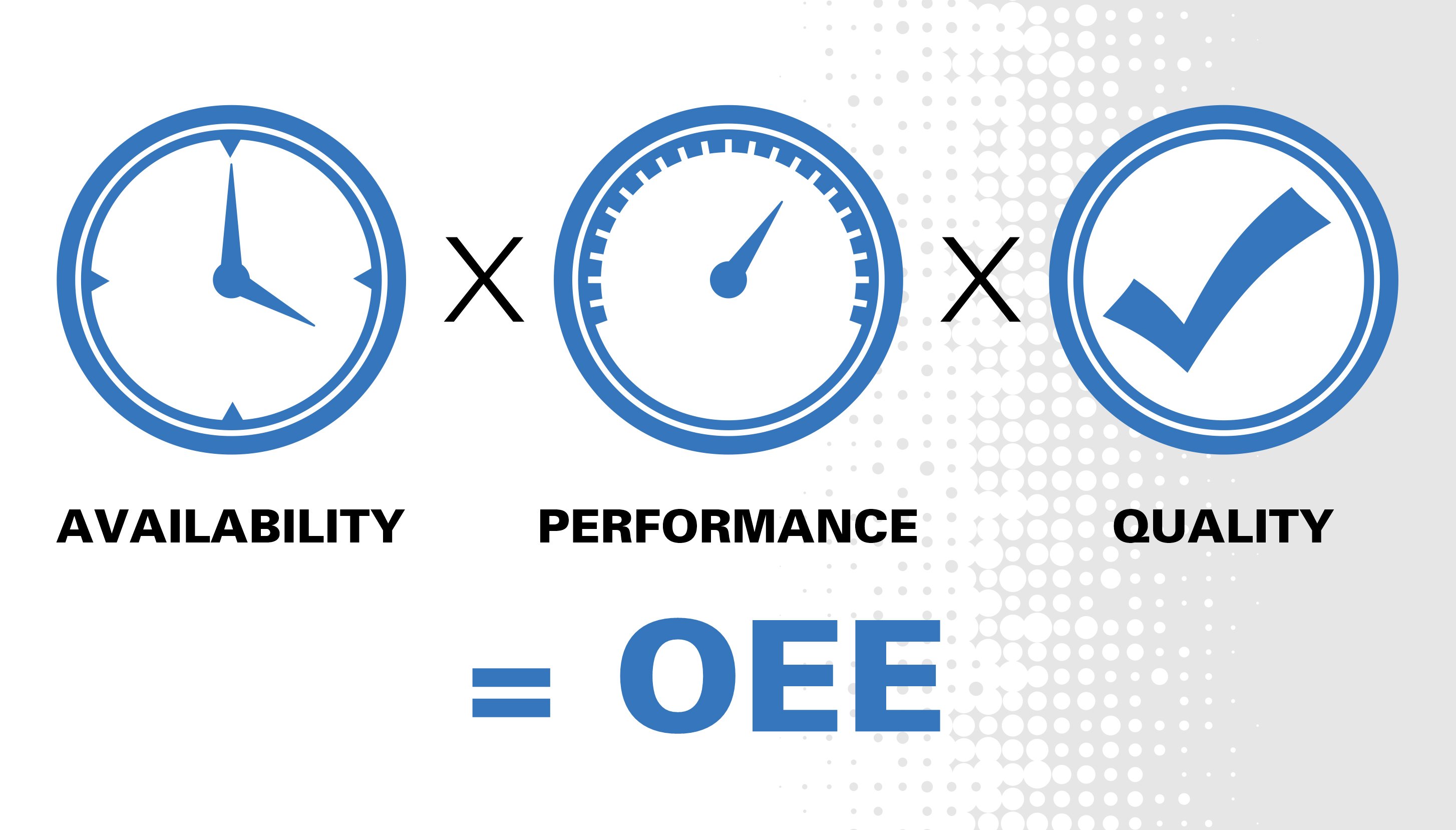

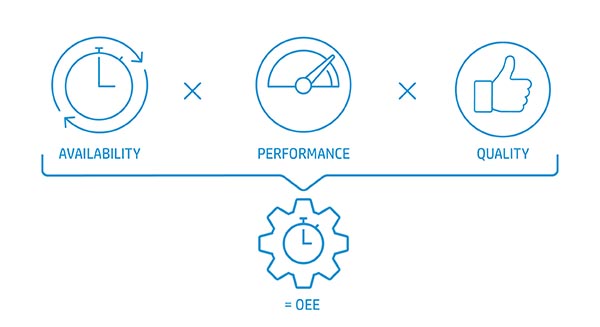

Oee = availability × performance × quality notice the interdisciplinary and collaborative nature of the formula. As a production management indicator, oee is used in industry to measure the. Focus your oee assessment first on.

7 tactics for improving oee across your plant and companywide production operations #1: Focus on the oee formula that fits your business connect oee with the manufacturing erp system utilize the internet of things perform routine preventive. Start from good overall equipment effectiveness takes your manufacturing.

The easiest way to improve your facility’s oee value is to target the component kpi that is furthest from the gold standard. Each of these elements are considered below along with typical. How to improve oee in manufacturing applications here are three ways that oee can be applied to achieve a more useful and productive manufacturing process: